There are several ways to reduce the risk of cavitation occurring. The most important one is to understand what Net Positive Suction Head (NPSH) is. That’s because awareness of NPSH helps to ensure proper pump selection for your system. Other ways to reduce cavitation risk include:

- Increasing liquid level or maintaining a minimum level (e.g., Eliminating flow restriction on the suction side by minimizing turns and elbows, and increasing pipe diameter)

- Installing an inducer on the pump, if applicable

- Using a VFD to reduce RPMs

NPSH is the difference in energy at the pump’s suction flange and the fluid’s vapor pressure. NPSH can be divided into two categories:

- NPSHr, required by the pump

- NPSHa, available through system suction

Doing the Math

The NPSHa is NPSH minus frictional loses in the pipe and the relative height differential between the pump inlet and the surface level of the fluid, which could be added or subtracted depending upon whether the pump inlet is above or below the fluid’s surface level.

NPSHr is the amount of internal pressure the system needs to prevent fluid vaporization, also known as cavitation. This information is provided by the pump manufacturers through experimental testing. To give you a better understanding of NPSHa, the diagram below provides you with a schematic of a simple pumping system.

Please note that the formula below the diagram is valid only for systems that are open to the atmosphere. In "closed systems" that are not open to the atmosphere, vapor pressure becomes suction pressure (unless blanket pressure is added), cancelling itself out and leaving us with differential height (Z) and frictional losses (Hf) for calculating NPSHa.

.jpeg?width=700&height=378&name=WVCC%20--%20NPSHa%20Drawing%20(March%202021%20eNewsletter).jpeg)

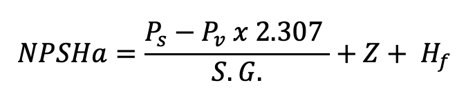

To calculate NPSHa, use this formula:

Where:

P_s= Absolute surface pressure in PSI (in an open system this is atmospheric or barometric pressure)

P_v= Vapor pressure of the fluid

S.G.= Specific Gravity of the fluid

Z= Relative height differential between the pump inlet and the surface level of the fluid

H_f= Head loss due to friction in the suction pipe

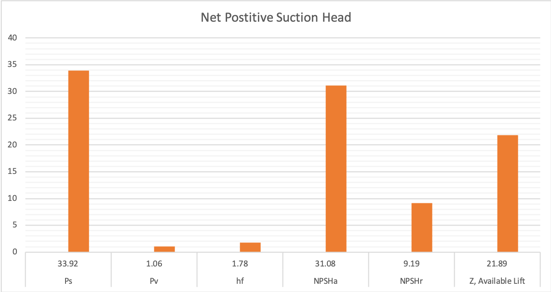

This example illustrates the concept of available NPSH (NPSHa):

Reducing Frictional Loss

Typically, frictional loss is the most difficult variable to quantify in the NPSHa equation because it’s largely dependent upon flow rate, suction pipe diameter and relative roughness of the pipe’s inner wall.

Frictional loss, H_f can be estimated using the Hazen-Williams Equation

After we know all the parameters, we can calculate the NPSHa to ensure cavitation does not occur within the pump or pumping system. NPSHr (required suction) must always be less than the NPSHa (available suction).

In last month’s newsletter, we discussed self-priming pumps. NPSH plays a role in the pump’s ability to suction lift. The maximum height any pump can suction lift is the difference between NPSHa and NPSHr .

For example, an open water sump application at ambient temperature requires a flow rate of 140 usgpm at a dynamic head of 130 ft. for which an Ansimag KP326 self-priming pump was sized. Based on the information given, the system provides 31 ft. of NPSHa. The pump sizing program tells us that the pump itself requires 9.2 ft. of NPSHr to operate properly. Therefore, the maximum distance the pump can suction lift and still function optimally is 31 ft.- 9.2 ft = 21.8 ft., meaning the fluid will vaporize at any distance greater than that number and potentially damage the pump.

To prevent cavitation from damaging your pumps…