While some can avoid mechanical seals altogether with magnetic sealless pumps, that option doesn’t work for every operation. If your process requires a pump with a mechanical seal, it’s essential to find the right seal and maintain it properly. The seal is designed to contain the fluid your pump is moving. As one of the most delicate parts of a pump, damaged or leaking seals are often the main cause of energy loss. Here are a few factors that affect the energy efficiency of your mechanical seal:

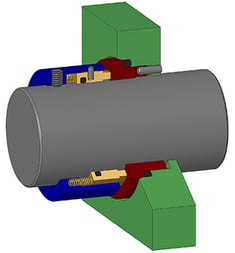

While some can avoid mechanical seals altogether with magnetic sealless pumps, that option doesn’t work for every operation. If your process requires a pump with a mechanical seal, it’s essential to find the right seal and maintain it properly. The seal is designed to contain the fluid your pump is moving. As one of the most delicate parts of a pump, damaged or leaking seals are often the main cause of energy loss. Here are a few factors that affect the energy efficiency of your mechanical seal:

1. Seal Size

The first thing to consider as you search for an energy-efficient mechanical seal is size. Small seals consume less energy than larger seals. A seal with a diameter of 1 to 2 inches will consume about 1 horsepower (hp) at maximum while larger seals can consume as much as 3 hp. While this amount of energy seems insignificant in the big picture, every little bit helps you improve the overall cost-efficiency of your pumping process.

2. Seal Flush Plans

For your seal to operate efficiently, it must be flushed with a lubricating fluid. You can reference the seal flush plans established by the American Petroleum Institute (API) to determine the best flush plan for your mechanical seal. A seal flush plan changes the environment where the seal operates. Seal flush plans create a stable environment for your seal to operate. Check out API Standard 682 to see flush plans for pump sealing systems.

3. Maintenance

Even with the right size seal operating in the right environment, your mechanical seal will face some wear and tear. You can prevent unexpected breakdowns and leaks with proper pump maintenance and care. A loose seal that leaks can cause significant energy loss especially if you’re moving heated fluids. Save yourself some time and money with the right mechanical seal and proper maintenance.

If you’re not sure how to keep your seal in prime condition, contact the experts at West View Cunningham. We can teach you how to select the right pump for your needs, interpret the API’s standards, maintain the pump, and prevent the seal from becoming loose or damaged.